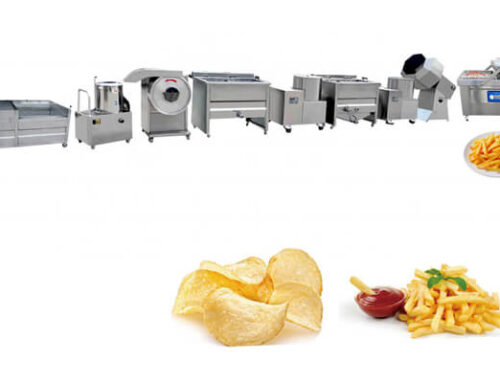

Automatic Frozen French Fries Manufacturing Plant Introduction

Main Equipment Show of Automatic Frozen French Fries Plant

➹ Washing & peeling machine: Suitable for washing and peeling the potatoes at one time.

➹ Potato cutting machine: It cuts potato into slices or strips; the thickness and size could be adjusted totally as your preference.

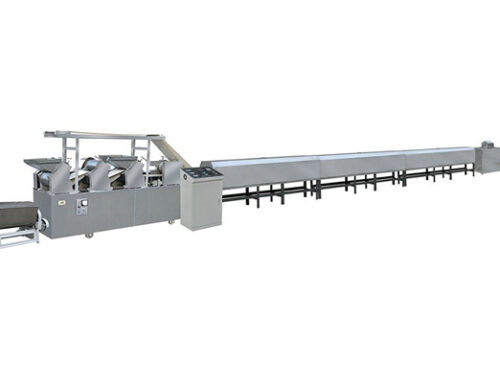

➹ Potato chips blanching machine: It is used for washing the French fries, making them look more attractive.

➹ Dewatering machine: Dewater the fries by air, saving the time of frying and improving the taste.

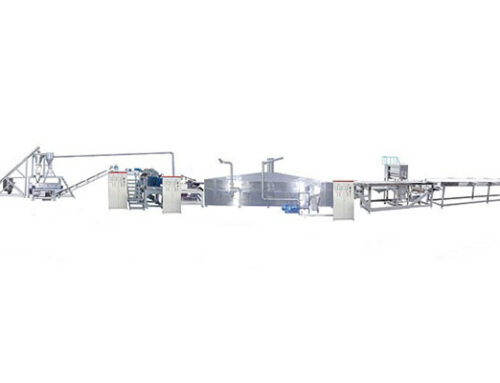

➹ Frying machine: Independently controlled oil temperature guarantees the good quality and taste of French fries. Oil stays at the top and water stay below. The residue will precipitate directly in the water and finally flow outside together with the water.

➹ De-oiling machine: Remove the extra oil from the fried French fries to reduce the oil content, make them more delicious.

➹ Chips packing machine: It can finish automatic feeding, elevating, weighing and packing the French fries at one time. High accuracy, no damage to the french fries.

Advantages of Automatic Frozen French Fries Line

1. Every machine is made of high-quality stainless steel, up to health standard, easy to clean.

2. The efficient automatic frozen French fries production line also can be adjusted to produce potato chips.

3. Low oil consumption, high automatic, high work efficiency, saves labor and energy.

4. Economical and practical, superior quality and competitive price.

5. 350-400kg/h, 600-700kg/h and 1000-1200kg/h, three capacity model for your choice.

6. We supply two types of production lines with different output capacity for your choice: semi-automatic fries production line and fully automatic production line.

Technical Data of 350-400kg/h Automatic Frozen French Fries Line

| No. | Name | Power/Voltage | Dimension |

| 1 | Elevator | 0.55kw/380V/50Hz | 2535*900*2150mm |

| 2 | Washing and Peeling Machine | 2.75kw/380V/50Hz | 3050*800*1600mm |

| 3 | Potato Picking Line | 0.55kw/380V/50Hz | 3700*1040*940mm |

| 4 | Elevator | 0.55kw/380V/50Hz | 1700*700*1740mm |

| 5 | Potato Cutting Machine | 1.5kw/380V/50Hz | 670*510*1400mm |

| 6 | Bubble Cleaning Line | 1.87kw/380V/50Hz | 3490*1450*1400mm |

| 7 | Blanching Line | 40.5kw/380V/50Hz | 5100*1070*1240mm |

| 8 | Rinsing Line | 1.87kw/380V/50Hz | 3490*1450*1400mm |

| 9 | Air-cooled De-watering Machine | 6kw/380V/50Hz | 4100*850*1840mm |

| 10 | Electrical Frying Line | 125kw/380V/50Hz | 5600*1700*2250mm |

| 11 | De-oiling Line | 6kw/380V/50Hz | 4100*850*1880mm |

| 12 | Picking Line | 0.55kw/380V/50Hz | 3560*700*1255mm |

| 13 | Packing Machine | 6kw/380V/50Hz | / |