Introduction of Tunnel Freezer

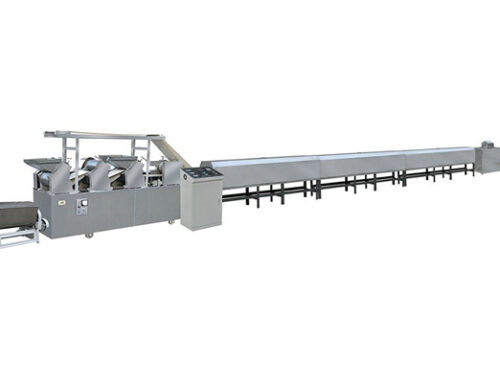

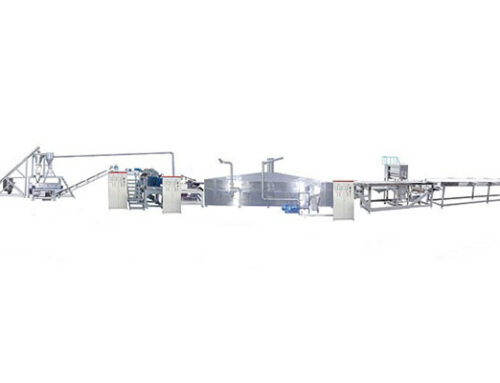

Tunnel freezing machine is a kind of food quick-freezing device with mature structure and stable performance. Its transmission structure is simple: the feeding and discharging position are low and convenient, easy to discharge. The output of the tunnel freezer varies from 500 kg/h to 1500 kg/h according to customer requirements. The professional tunnel freezer is specially designed for making frozen potato chips, patties, cut meat, fish and other seafood, etc. It is an efficient freezing device that can freeze a large number of products in a short period of time, and the center temperature of the quick-freezing products reaches -18℃so that no nutrient components are lost and the product’s appearance does not change color.

Types of Chips Tunnel Freezing Machine

According to the forms of the used conveyor belts, tunnel freezer can be divided into mesh-belt type quick-freezer and plate type quick-freezer. The mesh belts used in mesh belt type tunnel freezer are classified into stainless steel wire mesh and plastic steel mesh. The mesh belt type quick-freezing machine has a simple structure, reliable operation, and long service life which is widely used in the frozen food market. The mesh belt can be ventilated up and down, and the freezing speed is fast. And it is easy to realize fluidization by adding belt beating device and changing blowing method.

General specifications of Tunnel Freezer

| Model | WDSC-500 | WDSC-1000 | WDSC-1500 |

| Capacity(KG) | 500 | 1000 | 1500 |

| Feed temperature(℃) | +15 | +15 | +15 |

| Discharge temperature(℃) | -18 | -18 | -18 |

| Freezing temperature(℃) | -35 | -35 | -35 |

| Cold consumption(KW) | 95 | 180 | 270 |

| Installed power(KW) | 17.5 | 29.5 | 41.5 |

| Dimension(m) | 11.8*3.5*3 | 16.0*4.0*3 | 19.0*4.5*3 |

Structural Features

- High-strength stainless steel mesh belt is made of 304 high-elastic food-grade stainless steel wire. The mesh belt is suitable for freezing different sizes of frozen products, and the unique smooth mesh surface leaves almost no imprint on frozen products.

- The internal and external frame structure is made of food-grade stainless steel, and the part which has contact with the mesh belt is ultra-high molecular weight polyethylene with abrasion-proof performance in order to extend the life of the equipment. The main drive sprocket, chain, drive bearings and bearing seats are made of stainless steel, and the installation uses stainless steel overhead floor stand, the machine can be installed on the ground without special requirements, easy to clean, greatly reduce the bacteria breeding.

- Durable: The drums and mesh belts are covered with nylon for protection, extending the service life of the mesh belts.

- The mesh belt is optionally equipped with a strong pump cleaning. Cleaning and drying of the mesh belt at any time to ensure the hygiene of the conveyor belt.

- European advanced technology is adopted for chain transmission control, and the frequency conversion control is adopted for the belt working, and the speed can be steplessly adjusted. The freezer is equipped with stainless steel electric control cabinet: it has digital displaying function inside the freezing chamber and the entire equipment is reliable!

- Mesh belt mechanism adopts expansion structure adjustment to automatically repair the device to prevent the belt from deviating and loosening, improve the smooth running of the belt, and prolong the service life.

Tunnel Quick-freezer Advantages

Innovative science and technology, leading fresh life

The freezer is designed and manufactured in accordance with HACCP requirements to ensure food hygiene and safety, and the machine is made of double-sided stainless steel polyurethane heat insulator body plate, the door is double-layer sealed with electric heating, effectively prevent freezing. Since it is seamless so that it will not accumulate dust, and it is easy to clean. And the insulation effect is good which can keep the cold air firmly locked in the freezing chamber, obvious energy saving effect.

The air blowing method of the evaporator adopts the air guiding type, which generates the air channel in the freezer. Ensure that the wind direction of the mesh belt is even at any different position, so the effect of heat exchange is achieved, and the freezing efficiency is increased by 15%-20% compared to the conventional method, and the energy consumption of the frozen product is low.

Lasting “frozen” force, cold in the end

The quick freeze machine forms a strong cold air flow with a large vertical velocity upward and adopts a unique air guiding system to distribute the wind evenly and distribute the airflow evenly. The material is fully exposed to the strong cold wind. The lower part of the mesh belt is equipped with an independent pulse vibration device, so the gap of the mesh belt is not blocked by frost, which reduces the wind resistance and the air flow becomes smooth. And so that the material does not agglomerate and does not stick to form a monomer. The full-fluidization quick-freezing process is realized, the freezing speed is fast, and the frozen output is greatly improved.

Low-temperature compensation

Tunnel freezer has the function of automatic low-temperature compensation, which can automatically adjust the cooling temperature according to the external temperature change.

For example, in summer, the low temperature will be compensated automatically to avoid food decay and deterioration.

Low carbon environmental protection, farewell smell

Chips freezer adopts environmental protection antibacterial material which is after strict testing, eliminating the frozen odor and keeping original taste of food. No discoloration, no deterioration, and enjoy the freshness of food.

High Performance Tunnel Markets

- Fruits & vegetables

- Seafood

- Meat & poultry

- Dairy products

- Convenience food