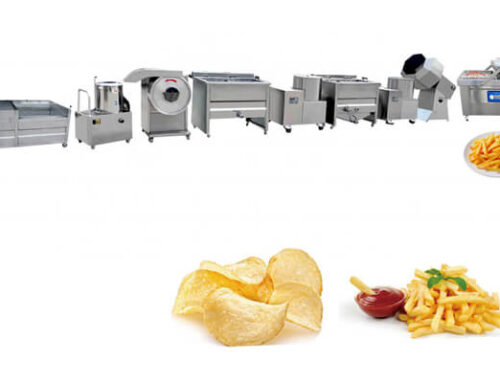

Automatic Potato Chips Packaging Machine

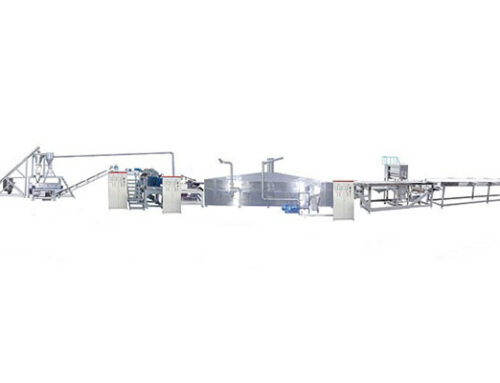

Automatic potato chips packaging machine is widely used in the automatic potato chips production line and frozen french fries line for packing potato chips and frozen fries. The potato chips packing machine can realize the automatic process of feeding, bag making, filling, date printing, inflating, counting and discharging. The bags can be the pillow or vertical type.

| Item | Details |

| Packing speed | 70 bag/min |

| Measuring Accuracy | ≤±1.5% |

| Bag size | (L)60-300 mm (W)90-200 mm |

| Max. Film width | 420 mm |

| Bag type | Pillow, Vertical |

| Filling range | 150-1300 ml |

| Film thickness | 0.04-0.09 mm |

| Packaging material | BOPP/CPP,PET/AL/PE, etc |

| Air consumption | 0.8Mpa 0.5m3/min |

| Total powder | 6.045 kW |

| Voltage | three phase 380V 50HZ |

| Air compressor | Not less than 1 CBM |

| Total height | 3760 mm |

Automatic Potato Chips Packaging Equipment Features

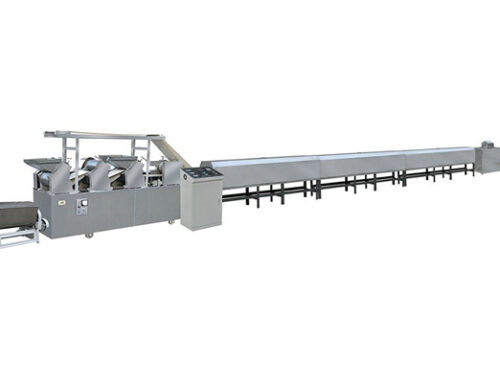

1. Fast in packing, high efficiency.

2. Full computer control system, human-machine interface, large touchscreen display, easy operation, intuitive and efficient.

3. Adopting servo film conveyor system, horizontal seal servo control, accurate positioning, excellent performance.

4. The machine can make pillow or vertical bag according to customer’s requirements.

Application

1. Automatic potato chips bagging machine is widely used in automatic potato chips production plant and frozen french fries production line.

2. Automatic french fries/ potato chips packaging machine can also be used for the quantitative weighing and packaging of peanuts, pistachios, melon seeds, jelly, biscuits, candy, chocolate, pet food, puffed food, ironware, plastic parts and other granulate, flaked, strip, materials with an irregular shape.

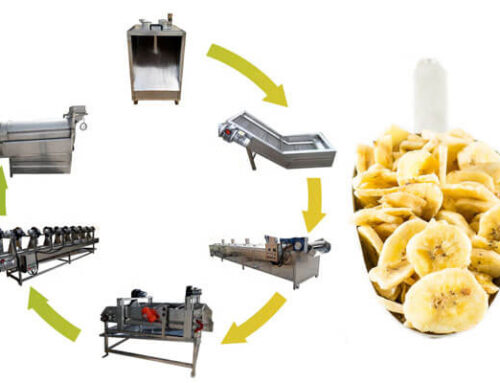

Working Process

Feeding bag→Coding→Opening bag→Measuring and filling→Heat sealing→Shaping and finished product discharging.

1. Put the potato chips/french fries/banana chips on the vibrating feeder.

2. The Z-type elevator will convey the product to the input hopper of the weighing system.

3. The weighing system will automatically weigh the product according to the preset figures.

4. The qualified product will fall into the bags for sealing process.

5. The packaged product will be discharged.