Introduction of Tablet Chewing Gum Forming Production Line

This automatic chewing gum forming production line is professional for producing tablet/piece type/flake chewing gum. This forming production line is forming, cutting, packaging for the integration of automatic production line, it is suitable for Chewing Gum in high capacity with high production efficiency. According to the customer’s request, it can be customized to produce different shapes and specifications chewing gum.

Main Performance of Tablet Chewing Gum Forming Production Line

1. Adopt unequal space screw pressing technology(no equidistant twin-screw extrusion technology), make the gum base free group even and chewing gum good taste.

2. Adopt frequency conversion control technology, make the machine work stable.

3. Adopt differential speed working principle, make chewing gum slice reliable and accurate.

Features of Tablet Chewing Gum Forming Production Line

1. Adopts the integration process of forming, cutting, packaging process, clear function, and organic combination, plan as a whole operation, can reach the assembly line process.

2. Mainframe with SS304 cover, material contacting parts uses food grade material.

3. The agitator is equipped with a lid. Shutdown protection: there is a timing protection (adopt time relay), manual operation stop protection, have open cover protection.

4. Gum base oven is processing customized, adopts SS material, equipped with 1 set of spare.

5. Equipped with an Industrial dehumidifier-5HP high-temperature constant temperature refrigeration dehumidifier, can make the refrigeration efficiency improving 5%, anti-corrosion and prevent mold, odor-free functions, won’t cause the accumulation of water plugging effect heat transfer.

6. Pastry rolling machine is equipped with a powder feed cooling device, convey cooling device, 6 layers rollers adopt water cycle cooling, auto sprinkle powder device.

7. Automatic packaging machine adopts high-quality electrical components, PLC control, packing speed adopts frequency conversion stepless speed adjustment.

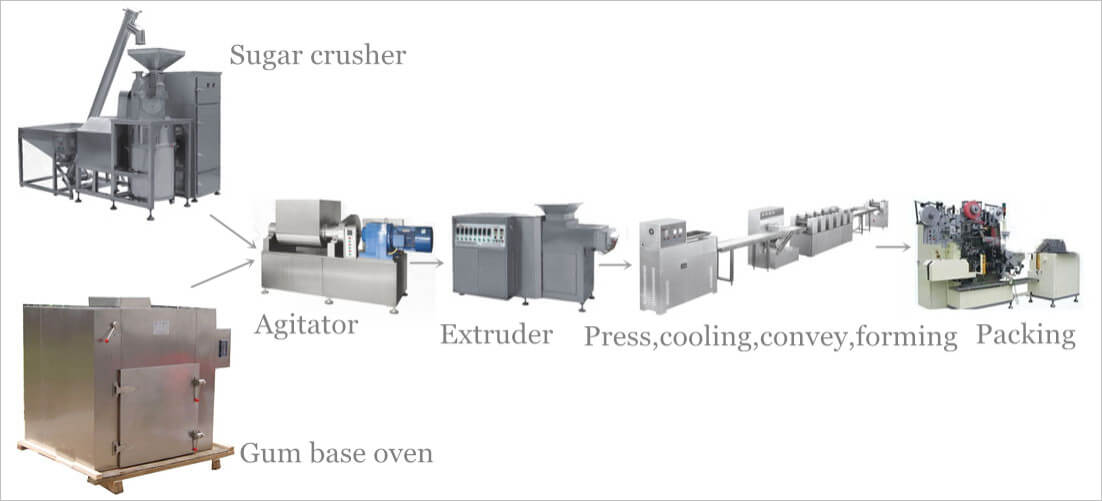

Product Process of Tablet Chewing Gum Forming Production Line

| Sugar crusher Gum base oven |

>Agitator→ Extruder→ Sprinkle powder and press→ Suck powder, cooling, convey→ Forming→ Packaging |

Main Technical Parameters of Tablet Chewing Gum Forming Machines

| Name | Power | Dimension | Weight | Capacity |

| Sugar Crusher | 17kw | 3000*1500*2200mm | 400kg | 500Kg/h |

| Gum Base Oven | 9kw | 2400*720*1600mm | 750kg | 12 trays |

| Industrial Dehumidifier | 4kw | 44*95*186cm | * | 12kg/h |

| Agitator | 20kw | 2300*890*1400mm | 1500kg | 500kg/h |

| Extruder | 11.7kw | 1650*480*1250mm | 800kg | * |

| Tablet Machine | 7kw | 6500*750*1900mm | 1800kg | * |

| Powder Sprinkler | 1.1kw | 4200*380*930mm | 400kg | * |

| Cooling Conveyor | 0.75kw | 1000*2000*800mm | 150kg | * |

| Scroll Cutter | 1.5kw | 760*780*1150mm | 350kg | * |

| Automatic Feeding/Dust Cleaning/Crusher | 17kw | 3000*1500*2200mm | 400kg | * |

| Automatic Packaging Machine | 6kw/380V | 5000*2000*2000mm | 2600Kg | 550-700 pieces/min/110-140 bags/min |